Your Cart is Empty

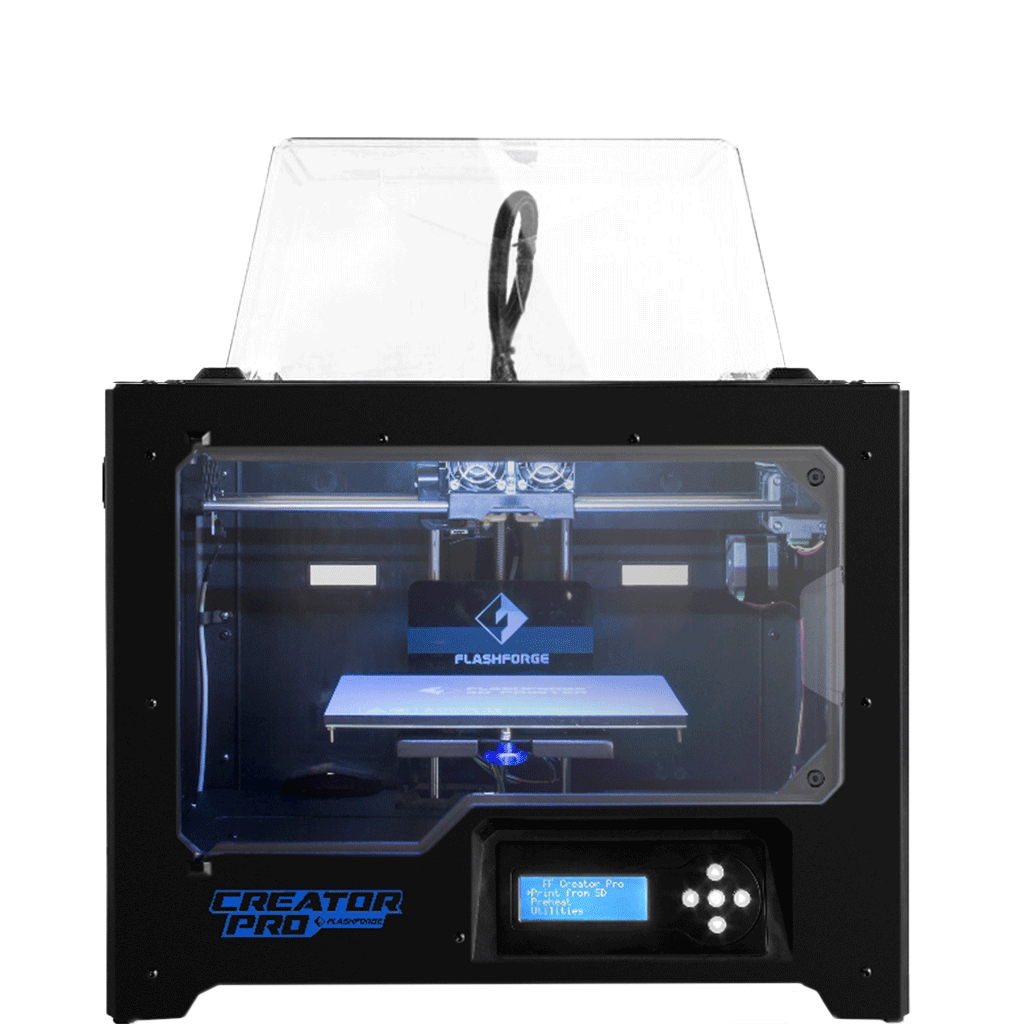

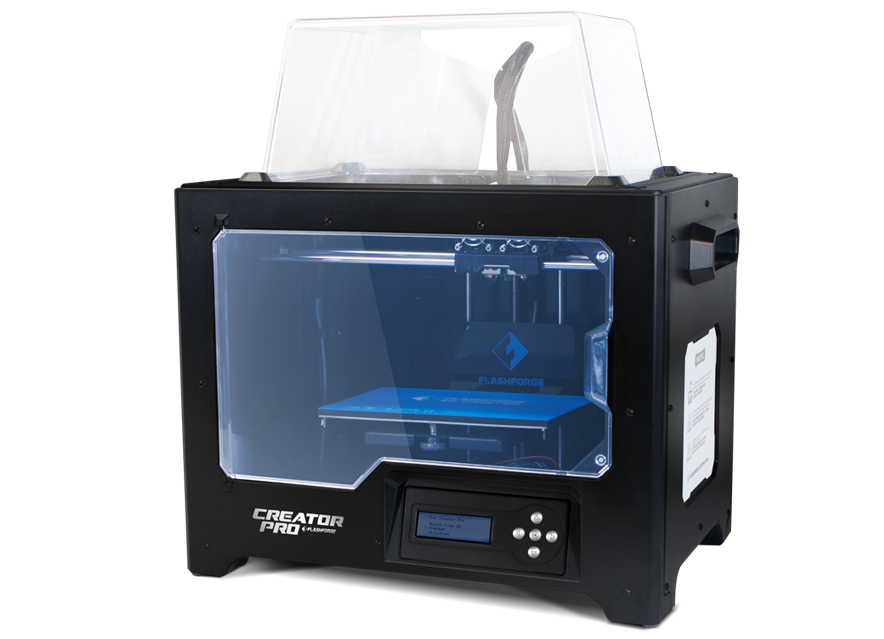

It is compact and refined with structural improvements to the chassis- utilising pressed aluminum, increasing rigidity and ultimately improving print quality. Enhanced ergonomics, calibration thumb screws, LED display and keypad. The incorporation of injection molded and panels, door and hood, improving the effectiveness of the heat retention chamber which reduces warping of ABS 3d printed parts. This sleek machine certainly looks the part and is a serious performer. You can now use the powerful and user friendl Flashforge Flashprint 3d slicing software with this machine.

The all new Flashforge Creator Pro can print large 228 x 148 x 150mm models

Flashforge Creator Pro for 2020

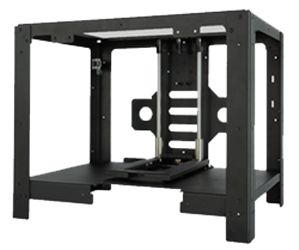

The Creator Pro is the next Generation 3D Printer from Flashforge, based on the proven and highly popular Creator and Creator X models, this 3D printer now includes a rigid metal frame and a precise casting aviation heating bed with greater flatness and even heat distribution, 3 point calibration as well as high quality dual extrusion technology optimised for both ABS and PLA. This new design allows higher levels of precision, ease of use and durability. Additionally, this printer now comes fully enclosed further improving the print quality and reduced warping of printed parts. The touch screen ergonomics have also been improved from its predecessor.

This 3D Printer has become available thanks to open source technology. With an improved design and at less than two thirds the price of the original, it is the best value fully capable Dual Head 3D printer on the market.

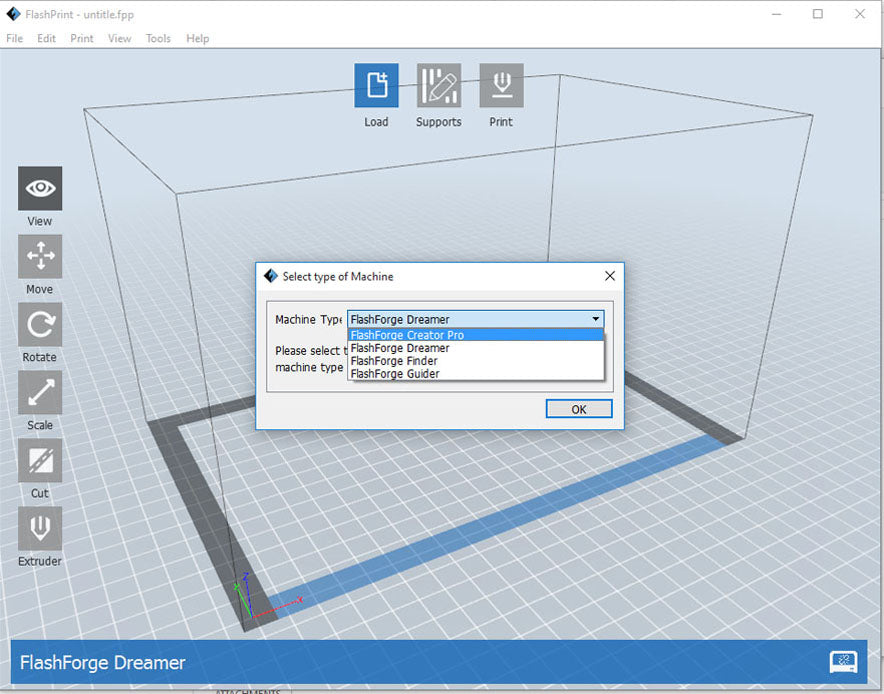

The Creator Pro 3D Printer is compatible with open source ReplicatorG or MakerWare controlling software which is used to control the MakerBot Replicator, Thing-O-Matic, CupCake CNC, RepRap and other generic CNC machines.But now you can also use the Flashforge Flashprint slicing software as well.

Flashforge have developed their own easy to use 3D printer software - Flashprint which can generate gcode files or send directly to the printer via USB or SD Card. You may also use open source and third party 3D Printing slicing software with the FlashForge Creator Pro such as Simplify3D.

The Flashforge Dreamer is a high performance, easy to use 3d printer and offers excellent value. Flashforge is fast becoming the largest 3d printer company in China for good reason!

The Flashforge Flashprint 3D Printing software that comes standard with these printers has seen a number of advancements. Although being very easy to use, it now includes some of the most advanced features that we have seen in 3d slicing programs. You can now generate your own custom support structures. Let the software automatically generate them, or add and subtract them at will.

The Flashprint 3D Slicing software will now automatically build tree like support structures, plus you can build your own with just a few clicks. This powerful feature is especially ideal for creating support structures for thin structured objects with fine detail.

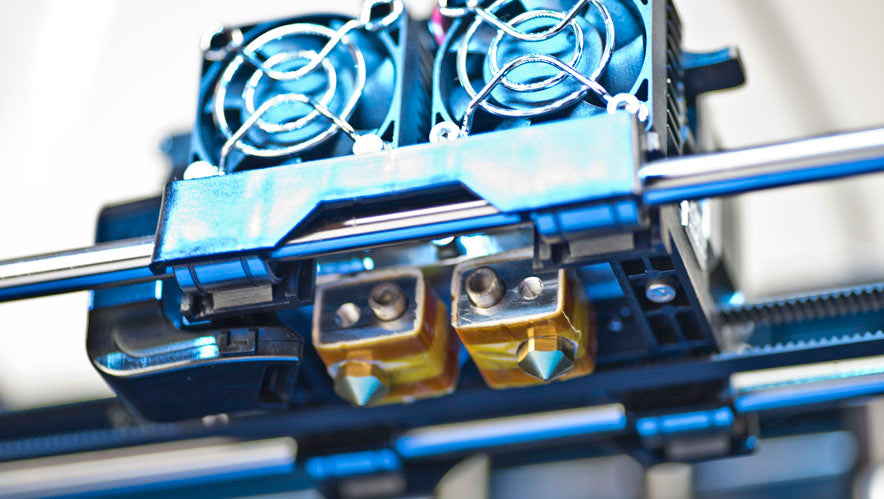

With further improvements from the original design including improved electronic circuitry, a higher 0.1mm Z resolution, a refined MK10 print head and the addition of a cast aluminum heated build platform, allowing for printing in ABS and PLA plastic.

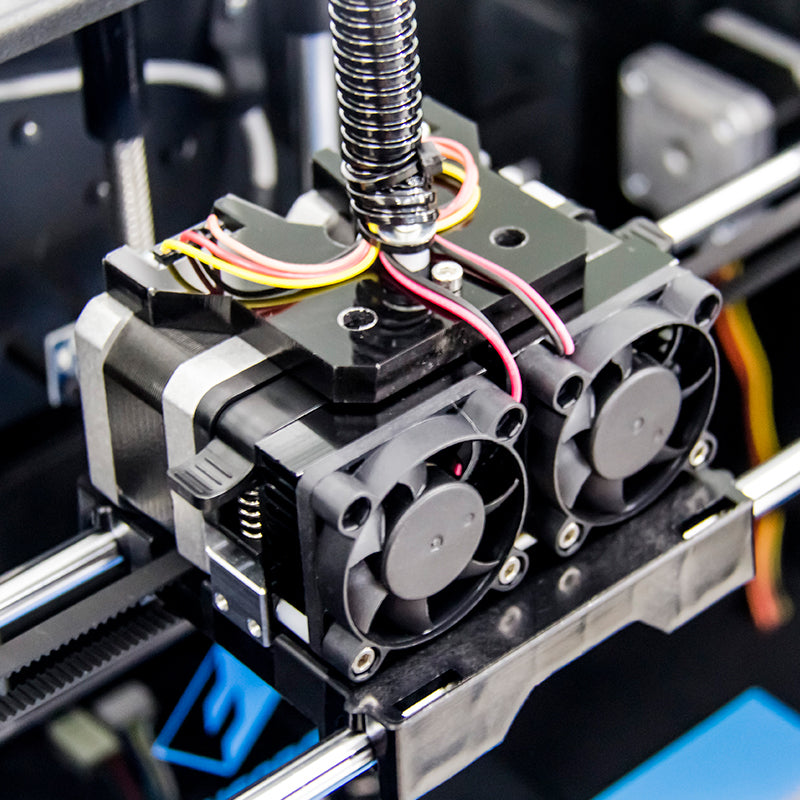

The left print head is optimised for PLA with integrated fan, whilst the right extruder is optimised for ABS

If this is not the best value low cost dual head 3D printer on the market, let us know, because we want to know about it!

Sturdy Construction-The creator Pro is encased in an pressed aluminum chassis for greater durability and rigidity as well as improved print quality due to reduced jitter during high speed prints.

Fully Enclosed-Side walls are now enclosed, and there is now an injection molded door and canopy- further reducing susceptibility sound resonance and improving print quality and significantly reducing warping of printed parts.

The canopy of the new Creator Pro is now injection molded with extra RGB LED lights for extra Bling!

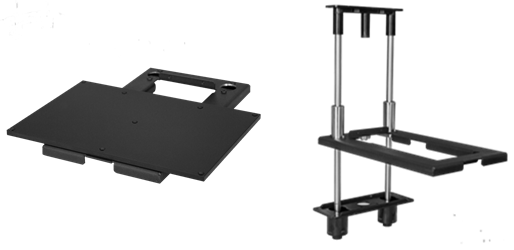

Improved Heated Build Platform-The Creator Pro includes an improved 6.3mm aluminum heat bed which has great flatness and a more even heat distribution, enabling more precise prints and better part adhesion. This platform can be heated up to 120℃, enabling the printer to print in ABS an HIPS plastic. Additionally the head be now includes an 3 point bed leveling system which simplifies the calibration the build platform. The Z axis has also been improved with increased rigidity and improved print quality, now with 10mm Z-axis Rods & Metal Supports.

Improvements of the Flashforge Creator Pro included a solid cast aluminum heat bed and 10mm Z axis rods.

Full Metal Jacket- When it comes to print quality, a rigid frame is the essential. The Flashforge Creator Pro sturdy stiff metal frame dampens vibration, reducing noise and jitter -maintaining higher print quality at high speed.

The MK10 Dual Extruder Head-

The Mk10 extruder head is suitable for printing PLA, PVA, ABS, HIPS, Flexible and new materials such and metals filled. It includes spring loaded tensioner, ensuring optimal reliability of the filament feeding mechanism. It incorporates a quality Nema stepper motor, polyoxymethylene injection molded and CNC machined aluminum parts as well as roller bearings for smooth axial motion and low friction teflon tubing, ensuring quality and reliable printing.

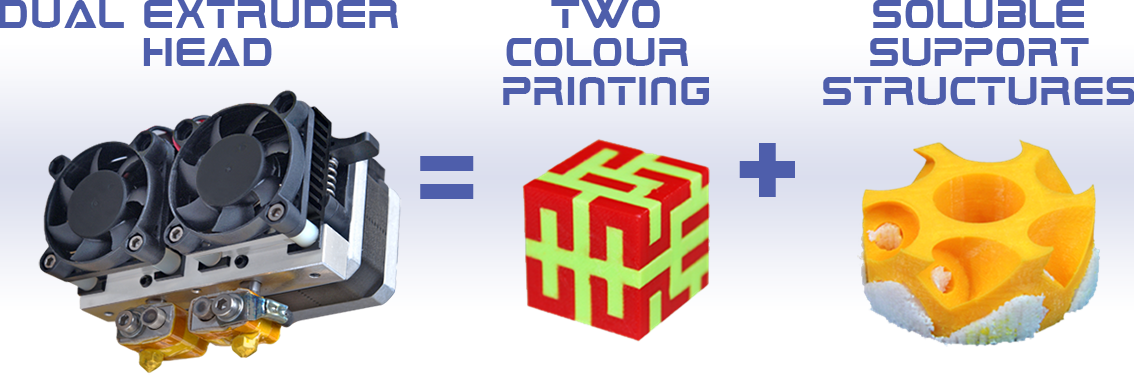

Dual print heads empower your creativity by enabling the production of two colour parts. Additionally the second print head can be used to print soluble support structures. No more cleaning up of complex supports inside internal cavities, now you can print in water soluble PVA, Lemonine soluble HIPS or Caustic soda soluble PLA.

Two Heads are better then one- The Flashforge Creator Pro can print two colour parts and soluble support structures.

Nice rear end, now injection molded with all cabling recessed away from the moving parts

Whats in the Box-

Flashforge Creator Pro 3D Printer

USB Cable

Power Cable (AU)

4GD SD Card

Accessory bag containing nuts, screws, and hex wrench set

Two x 1kg roll 1.75mm filament (usually 1 x ABS and 1 x PLA but may be random)

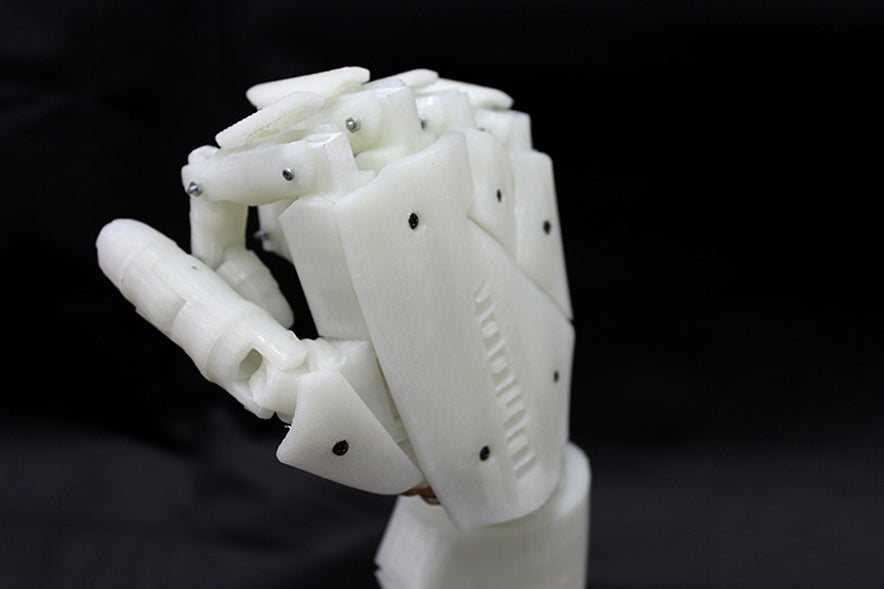

Fine Detailed Printing-

When it comes to 3D printers, the proof is in the print quality. This is where the Flashforge Creator Pro 3D printer delivers. No other printer gives you so much performance for such a small price tag. This is the best value low cost printer on the market today!

Downloads-

Flashforge Dreamer User Manual pdf

Specifications-

| Print volume / build size (X,Y,Z) | 5 litres(227x 148x150) |

mm |

| Frame size (X,Y,Z) | 476x332x383 | mm |

| Resolution (Z-AXIS) | 0.1 - 0.3 | mm |

| Accuracy (Theoretical positioning resolution) | Z axis 0.0025, XY axis 0.011 | mm |

| Print Speed | 40-150 | mm/sec |

| Total mass | 13.5 | kg |

| Nozzle diameter | 0.4 | mm |

| Nozzle Flow Velocity | 24 | cc/hr |

| Recommended Nozzle Temp | 230 for ABS | ℃ |

| Filament Diameter | 1.75 | mm |

| Filament Material | ABS, PLA, PVA, HIPS, Nylon etc | |

| Slicing Software | Flashprint / ReplicatorG / MakerWare / MakerWare Desktop | |

| OS Support | Windows 7, Linux, Mac OX | |

| Print without PC | Yes with SD card (included) or USB link (firmware update only) | |

| Heated Bed included | Yes up to 120 | ℃ |

| Power Consumption | 220V, 350W | |

| Extruder Heads included | 2 | |

| Comes with 12 Month Parts Replacement Warranty | ||

Download the Flashforge Creator User Manual Here-Download the latest vesion of Flashprint Here- |

|